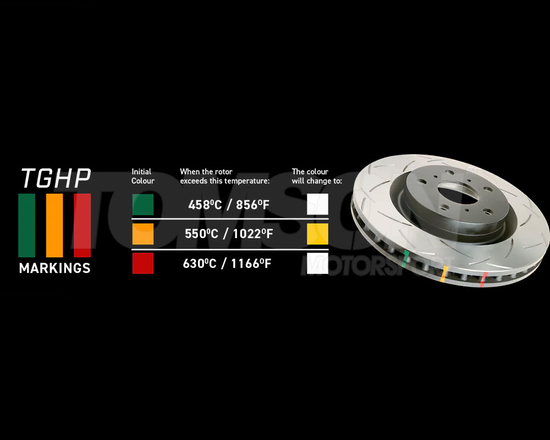

DBA DBA2572S Street T2 Slot brake rotor Mazda MX-5 (ND, RF) 1.5 258 mm (front)

For: Mazda MX-5 (ND, RF) 1.5

DBA’s patented T2 slot design is for demanding applications where consistent friction is required.

The development of the revolutionary bi-directional slot design eliminates the concern of having opposing left and right designated brake rotors, with DBA T2 and T3 rotors able to be used on either side of your vehicle.

T2 slots increase the number of out-gassing exit points on the rotor surface, assisting in the removal of unwanted dust and debris between the rotor and brake pad, which otherwise could cause pad glazing and loss of brake performance.

The bi-directional slot design also assists in dampening the vibration harmonics (noise), resulting in a quieter, more responsive and smoother brake pedal feel.

- Revolutionary bi-directional slot design

- Multiple curved slots for maximum strength.

- Effective removal of brake dust and debris

- EEffective in maintaining consistent friction

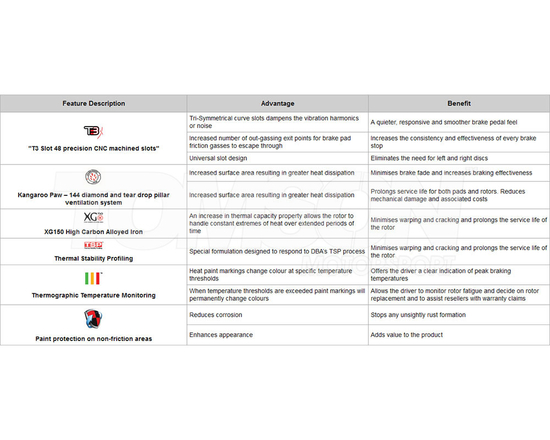

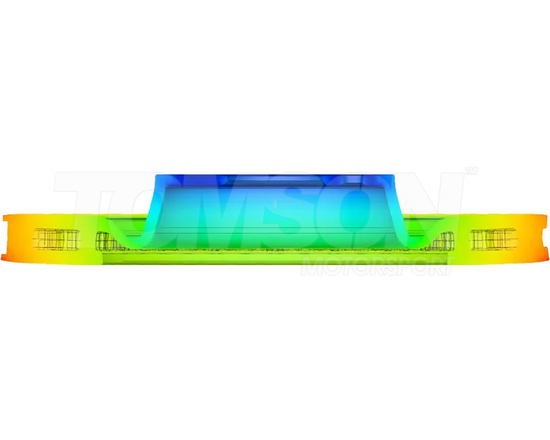

Kangaroo Paw Ventilation

- Home Grown Inspiration

Inspired within Australia’s heartland, DBA developed an entirely new rotor cooling design, known as Kangaroo Paw.

The patented Kangaroo Paw ventilation system provides a more efficient method of keeping the rotors cool under the heaviest braking applications.

Using a series of 144 diamond and teardrop patterned pillars (or columns) instead of conventional straight cooling vanes, the Kangaroo Paw design increases cooling efficiency by up to 20% when compared with most other conventional ventilated disc rotors.

- Better Core Strength

As well as providing cooler operating temperatures, the Kangaroo Paw system also provides additional support to the friction face. The Kangaroo Paw pillars are evenly spread across the disc face and make the rotor stronger, more stable and more consistent in operation.

This enables the rotor to maintain the fine tolerances over its lifetime better than a straight vane design, which can “balloon” and swell between the vanes when operating at high temperatures.

- Why Kangaroo Paw is a Better Ventilation System

The ventilation system of a brake rotor is best described as the foundation and support between the friction surfaces.

Other than material composition, another major factor that affects the thermal performance of brake rotors is the surface area within the ventilation design. The more surface area, the more heat that can be removed from the brake rotor.

The mass of the brake rotor also plays an important role. The greater the mass, the more heat that can be stored and must be dissipated, this is why the design of the Kangaroo Paw is so effective. This minimises the risk of brake fade and restores normal braking much sooner.

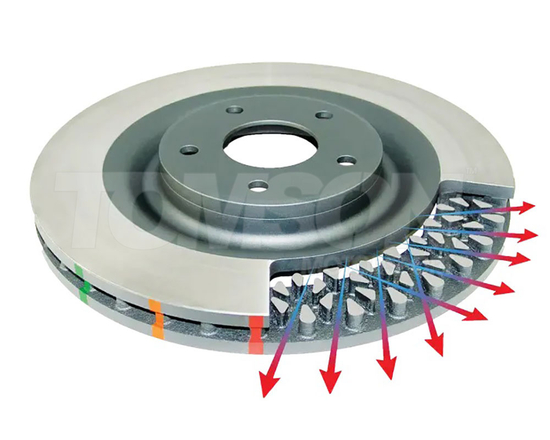

TGHP Thermo-Graphic Heat Paint

DBA’s patented Thermo-Graphic Heat Paint (TGHP) markings are a standard feature on all DBA 4000 and 5000 Series disc rotors.

The TGHP paint stripes of Green, Orange and Red will change colour once your DBA rotor reaches predetermined critical temperature thresholds. Driver’s can monitor peak rotor temperatures to better understand the effects of their driving style and make informed choices in pad selection or whether their driving style is best for the application.

TGHP colour coding is incorporated with DBA’s range of Performance Pads, with the Performance Pads colour coded to the heat thresholds. When your TGHP stripes change colour, you should ensure you have the right DBA pads to match.

XG-150 Performance Materials

After 30 years of design and development with race teams around the world, Disc Brakes Australia developed a proprietary cast iron formulation (XG-150) for use in all of its premium performance disc brake rotors.

DBA’s XG-150 grey iron is high in carbon and alloyed to produce excellent thermal and noise dampening characteristics. This is combined with our patented Kangaroo Paw ventilation design to provide the ultimate in structural strength, noise dampening and thermal stability.

DBA’s proprietary TSP process is applied to the XG-150 iron to condition the metal for heavy duty applications involving high stress and frequent thermal cycling such as extreme 4WD, towing heavy loads or high-performance cars on the street or track.

TSP Thermal Stability Profiling

Thermal Stability Profiling (TSP), is a DBA proprietary process, developed for use with all 4000 and 5000 Series high carbon disc rotors.

Under the TSP process, XG-150 grey iron is subjected to prolonged heat cycles under strictly controlled conditions, to relieve any internal stresses sustained from the manufacturing processes. This ensures maximum thermal stability and reduced metal fatigue in extremely high demanding applications.

DBA’s comprehensive materials testing both on the race track and in computer simulations has enabled the development of this temperature cycling process to optimise the disc rotor material prior to fitting on the vehicle.