DBA DBA53298SLVXD 5000 T3 Slot 2-Piece brake rotor BMW M2 Competition (F87), M3 (F80), M4 (F82, F83) 3.0 S55B30 380 mm (front)

For: BMW M2 Competition (F87), M3 (F80), M4 (F82, F83) with 3.0 S55B30 engines

DBA 5000 T3 slot design ‘sports’ the same benefits as the 4000 SERIES except for one major structural advancement. The 5000 SERIES brake rotors incorporate Alumalite hats made from 6061-T6 Aeronautical grade aluminium. The Alumalite hat reduces unsprung weight for improved suspension and handling performance as well as allowing uniform expansion of the disc rotor during high performance use. The Alumalite’s ability to reduce the level of heat transfer adds to the longevity of both the disc rotor and other vehicle components such as brake pads and wheel hub bearings.

The tri-symmetrical slots also increase the number of out-gassing exit points for brake pad friction gases to escape through, further increasing the consistency and effectiveness of every brake stop.

Designed for extreme road and race applications.

Home grown inspiration

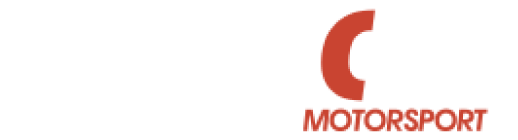

Inspired within Australia’s heartland, DBA developed the Kangaroo Paw cooling system. This patented ventilation system provides a much more efficient method of keeping the rotors cool under the heaviest of braking applications.

Dimensionally precise

Friction surface is CBN (Cubic Boron Nitride) machine turned for improved DTV (Disc Thickness variation) and parallelism. This provides a more dimensionally precise and stable surface finish when compared to ‘ground’ finished disc rotors.

Thermo-graphic Temperature Monitoring

4000 and 5000 Series rotors also incorporate DBA’s Thermo-Graphic heat paint markings which change colour when specific temperature thresholds are achieved. By monitoring the markings, drivers can check their braking performance quickly and easily.

High Carbon Alloyed Iron

Through extensive testing and feedback from performance drivers worldwide, DBA has developed a unique cast iron formula (XG-150) for use in all of it’s CLUBSPEC disc brake rotors. The XG-150 formula, with it’s increased thermal capacity properties, is designed to respond to the DBA TSP process allowing the rotor to handle constant extremes of heat over an extended period of time.

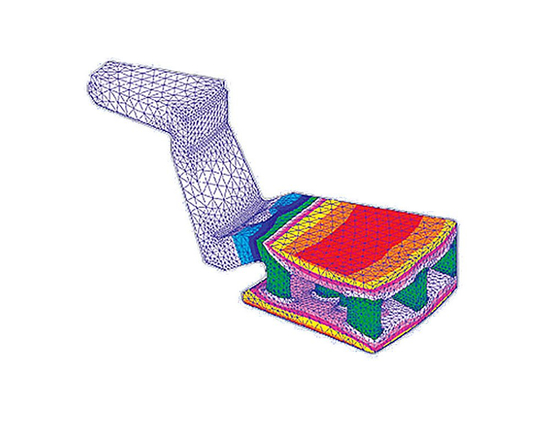

Thermal Stability Profiling (TSP)

TSPTM is a process of relieving the stresses that are naturally generated in the casting and manufacturing processes. This process stabilises the stresses by re-aligning the microstructure of the iron, resulting in a disc rotor ideal for heavy road braking and race applications.

| Description | Advantage | Benefit | |

|---|---|---|---|

| "T3 Slot 48 precision CNC machined slots" | Tri-Symmetrical curve slots dampens the vibration harmonics or noise | A quieter, responsive and smoother brake pedal feel | |

| Increased number of out-gassing exit points for brake pad friction gasses to escape through | Increases the consistency and effectiveness of every brake stop | ||

| Universal slot design | Eliminates the need for left and right discs | ||

| Kangaroo Paw – 144 diamond and tear drop pillar ventilation system | Increased surface area resulting in greater heat dissipation | Minimises brake fade and increases braking effectiveness | |

| Increased surface area resulting in greater heat dissipation | Prolongs service life for both pads and rotors. Reduces mechanical damage and associated costs | ||

| XG150 High Carbon Alloyed Iron | An increase in thermal capacity property allows the rotor to handle constant extremes of heat over extended periods of time | Minimises warping and cracking and prolongs the service life of the rotor | |

| Special formulation designed to respond to DBA’s TSP process | Minimises warping and cracking and prolongs the service life of the rotor | ||

| Thermographic Temperature Monitoring | Heat paint markings change colour at specific temperature thresholds | Offers the driver a clear indication of peak braking temperatures | |

| When temperature thresholds are exceeded paint markings will permanently change colours | Allows the driver to monitor rotor fatigue and decide on rotor replacement and to assist resellers with warranty claims | ||

| Paint protection on non-friction areas | Reduces corrosion | Stops any unsightly rust formation | |

| Enhances appearance | Adds value to the product |