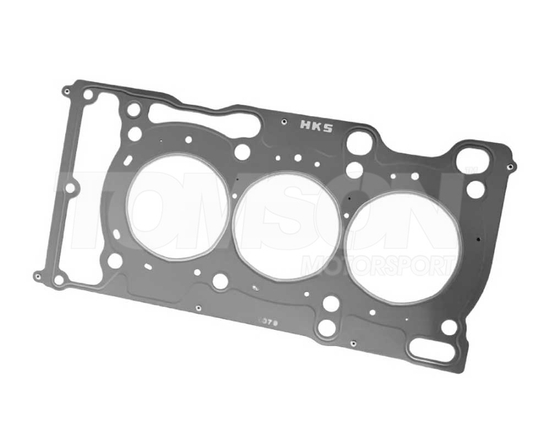

HKS 2301-RT042 head gasket (grommet type) Toyota GR Yaris (Gen 1) (GXPA16) 1.6 G16E-GTS 0.80 mm (dia. 89 mm)

For: Toyota GR Yaris (Gen 1) (GXPA16) with 1.6 G16E-GTS engines

HKS metal head gaskets are constructed from multiple layers of steel to ensure proper head to block sealing under the most demanding high performance conditions. In the construction of each HKS head gasket, a special metal which is extremely resistant to the severe levels of both heat and corrosion, that is attributed with high-horsepower and high-boost conditions, is used to ensure gasket integrity. Aside from the durable internal construction, all HKS head gaskets are also coated with a special fluorine rubber coating to provide the ultimate seal. HKS metal head gaskets are designed to accommodate for oversize pistons and altered compression ratios. For most engines multiple HKS head gasket thicknesses are available to change the dynamic compression ratio according to the needs and characteristics of the various levels tuning and engine conditions. While HKS head gaskets are an excellent addition to a performance engine, they are not designed to cure sealing problems caused by head or block irregularities.

The HKS Stopper head gasket is the most effective as it consists of the maximum layers of plates possible for the best possible sealing and durability. The increased sealing capability is also due to a molded stopper ring around each combustion chamber.

The HKS Bead head gaskets are popular because of their very effective sealing properties, structural design, and lower price. The raised bead structure around each combustion chamber ensures a tight seal for applications with high compression and high boost conditions.pplications.

It is a grommet-type gasket that can be used even if the boost is further increased with G16E-GTS for GR Yaris (Gen 1) with high combustion pressure.

Grommet type head gasket

Improves the sealing limit by securing the surface pressure of the gasket sealing surface by employing the grommet structure. It put the shims at either end of the engine deck to apply the load evenly when tightening the head bolt to prevent the distortion of the cylinder head.

Stopper type head gasket

A high pressure seal is formed around the combustion chamber through the use of stoppers which create a step within the gasket for optimum sealing. By making the stopper part of the plate also allows the fold to be smaller while maintaining structural integrity. One side of the plate is completely flat meaning that it can be layered with the stopper to allow stoppers to be used in even the tightest of locations around the combustion chamber forming a high quality seal. Compared with other gaskets of the same thickness, there are more layers in these gaskets giving flexibility which allows the gasket to maintain a good seal even when the engine tries to vibrate and move.

Opposed bead stopper type head gasket

If you don't have to worry about the distortion, you can use this to improve the sealing. This type is much better than bead type in matter of sealing. Opposed bead stopper type provide more balance in surface pressure.

Bead type head gasket

A bead is a type of spring used to maintain surface pressure which is very well suited to head gasket use. The beads are laid out to provide optimum pressure and seal around the combustion chamber. By carefully designing and adjusting the bead shape and heights, precise control of surface pressure is achieved for optimum results. Using a combination of 3 different types of beads allows maximum efficiency and performance.

Independent warter hole type

Water holes and Head Bolt holes have "independent bead" that is the mainstream technology in motor racing. It reduces possibility of overheating even combustion gas leakage due to high horsepower. Because of the new design of bead shape around Head Bolt hole and water hole, crack around Head Bolt hole will be prevented.